Cleaning commercial and industrial spaces has been a cornerstone of our business for decades. Carolina Services of the Triad has built long-term cleaning partnerships with private schools, offices, shipping facilities, medical centers, and industrial processing plants throughout the Piedmont Triad.

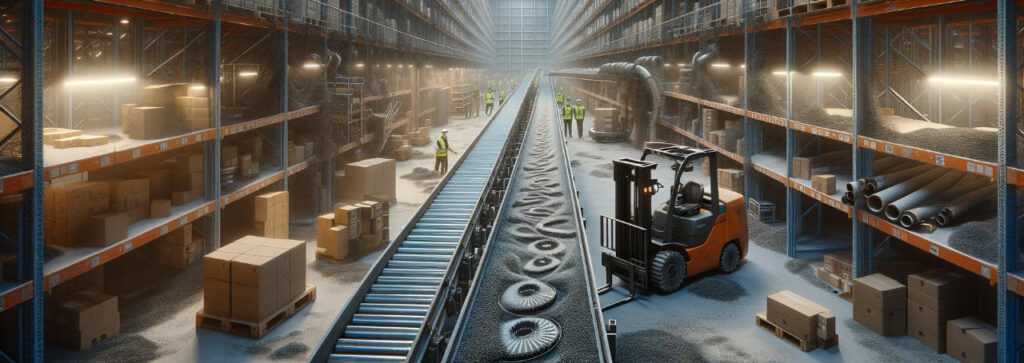

In today’s post we’d like to highlight some of the aspects that go into our industrial cleaning services. A safe environment is a profitable one, after all.

Here’s what we’ll cover:

- Common bacteria and contaminants found in industrial spaces

- Area-specific cleaning methods

- Ventilation system maintenance

- How to set and optimize a cleaning schedule

Common Bacteria Found in Industrial Spaces (and How We Decontaminate Them)

Staphylococcus aureus (Staph): Often found on human skin, these bacteria can easily contaminate surfaces in commercial areas like office areas, locker rooms, and cafeterias where employees gather.

Escherichia coli (E. coli): This group of bacteria is commonly associated with the gut of humans and animals, but certain strains can be pathogenic, leading to outbreaks of food poisoning. Facilities involved in food processing or handling must be particularly vigilant about this.

Pseudomonas aeruginosa: Known for its resilience, these bacteria can thrive in a wide range of environments, including water systems and damp areas, posing risks especially in facilities with complex plumbing or that use water in their processes.

Legionella pneumophila: This bacterium is responsible for Legionnaires’ disease and thrives in water systems, cooling towers, and humid environments, making buildings with extensive water-cooling systems potential hotspots.

Listeria monocytogenes: A concern in food processing and storage facilities, this bacterium can grow at refrigeration temperatures, making it a challenging pathogen to control.

Modern industrial cleaning teams are trained to identify and neutralize each of these threats using targeted, hospital-grade disinfectants and contamination control protocols. The result: a safer, more compliant workplace that supports both employee health and long-term productivity.

Custom Decontamination Methods for Different Areas of the Facility, From Office Spaces to Machine Areas

Each space within an industrial operation comes with its own cleaning challenges.

Equipment and Machinery Areas

Machines and assembly lines often accumulate grease, oil, and dust from production processes. Left unchecked, this buildup can cause safety hazards and degrade performance over time. Carolina Services of the Triad uses industrial-strength degreasers, pressure washing, and steam cleaning to remove these residues safely without damaging equipment.

Office and Common Areas

Office areas require a gentler approach. We use eco-friendly products to clean desks, floors, and electronic surfaces, preventing damage while maintaining a healthy indoor environment. High-touch points such as keyboards, light switches, and door handles are sanitized regularly to reduce germ spread.

Specialized Environments

Facilities that handle oil-based or food-grade products face unique cleaning demands. Our technicians develop site-specific protocols that combine powerful cleaners with safe techniques to protect both workers and equipment.

From top to bottom, our cleaning methods are adapted to the materials, workflow, and safety standards of your facility.

Workplace Ventilation System Facts

Air quality plays a major role in workplace safety and comfort. Factories and warehouses generate fine particles, fumes, and chemical byproducts that can circulate through HVAC systems if not regularly cleaned.

According to the EPA, indoor air can be up to 70 times more polluted than outdoor air in some industrial environments without proper filtration. In fact, 80% of HVAC equipment breakdowns are linked to dust and debris buildup.

Regular air duct cleaning in industrial settings ensures HVAC systems operate efficiently, reducing unnecessary energy consumption and extending the lifespan of expensive business equipment.

Routine duct cleaning and filter replacement keep air systems efficient, extend equipment lifespan, and protect employees from respiratory exposure—all of which support consistent productivity and lower maintenance costs.

Setting & Optimizing A Proper Industrial Decontamination Schedule

Activity and Risk

Imagine stepping into a bustling food processing plant, where customers rely on your consistency. Surfaces that touch the products must be sanitized continuously, ideally after every production cycle, to prevent cross-contamination. It’s a high-stakes game where the frequency of cleaning is dictated by the rhythm of business production and the uncompromising standards of commercial hygiene.

Contrast this with the gritty floors of a metal fabrication workshop, where sparks fly and dust settles like a thin veil over everything. The end of each shift marks the beginning of a cleanup operation, vacuuming the day’s toil away and checking air filters to maintain high breathability.

Here, daily disinfecting and safety cleanups are the drumbeat to which the facility marches, preventing the buildup from becoming a commercial nemesis.

Seasonal Shifts and Special Cleaning Circumstances

During peak production times — such as holidays in a distribution center or new product launches in a lab — cleaning demands often increase. Adjusting your schedule proactively prevents downtime and helps maintain compliance with health and safety standards.

Or picture a pharmaceutical lab, where the introduction of a new product line might bring with it a slew of additional cleanliness protocols. These special circumstances aren’t just blips on the radar; they’re opportunities to adapt and refine your cleaning regimen, ensuring it’s as dynamic as the facility it supports.

Partner with a Proven Industrial Cleaning Team

At Carolina Services of the Triad, we help businesses throughout High Point, Greensboro, Winston-Salem, and surrounding areas maintain safe, healthy, and efficient work environments. From industrial deep cleaning to ongoing sanitizing programs, our trained professionals ensure your facility meets the highest standards of cleanliness and compliance.

Ready to discuss your facility’s cleaning needs?

Contact us today to schedule a consultation and discover how our industrial sanitizing solutions can support your operation.